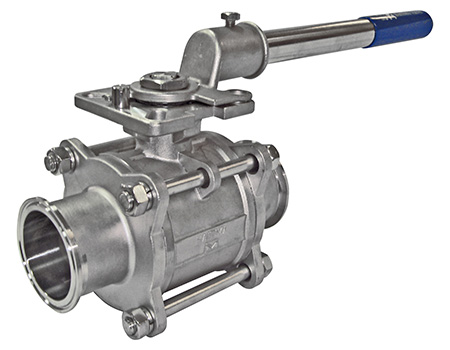

2013KC

FEATURES

- Clamp end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Clamp End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Live-loading design

- Anti-static device (option)

- Cavity filled seats

- Locking device

- ISO 5211 Mounting pad

2013KC-BPE:

- Clamp end castings have low sulphur content of 0.005-0.017%

2013CM

FEATURES

- Clamp end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Clamp End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Cavity filled seats

- Locking device

- ISO 5211 Mounting pad

2013CD

FEATURES

- Clamp end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Clamp End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Live-loading design

- Cavity filled seats

- Locking device

- ISO 5211 Direct mounting pad

- DIN 32676-B clamp end

- 2013CDA (option)

- Automation accessories (option)

- Spring return handle (option)

2057C

FEATURES

- Clamp end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Clamp End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Live-loading design

- Anti-Static Device (option)

- Cavity filled seats

- Locking device

- ISO 5211 Direct mounting pad

- Automation accessories (option)